Concrete boxes M-Series

A membrane box for a flexible installation

Multitalents in prefabricated concrete

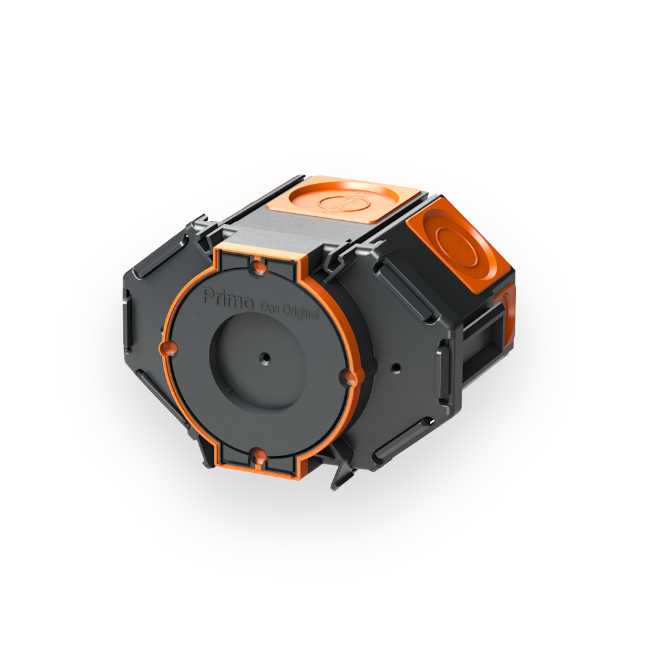

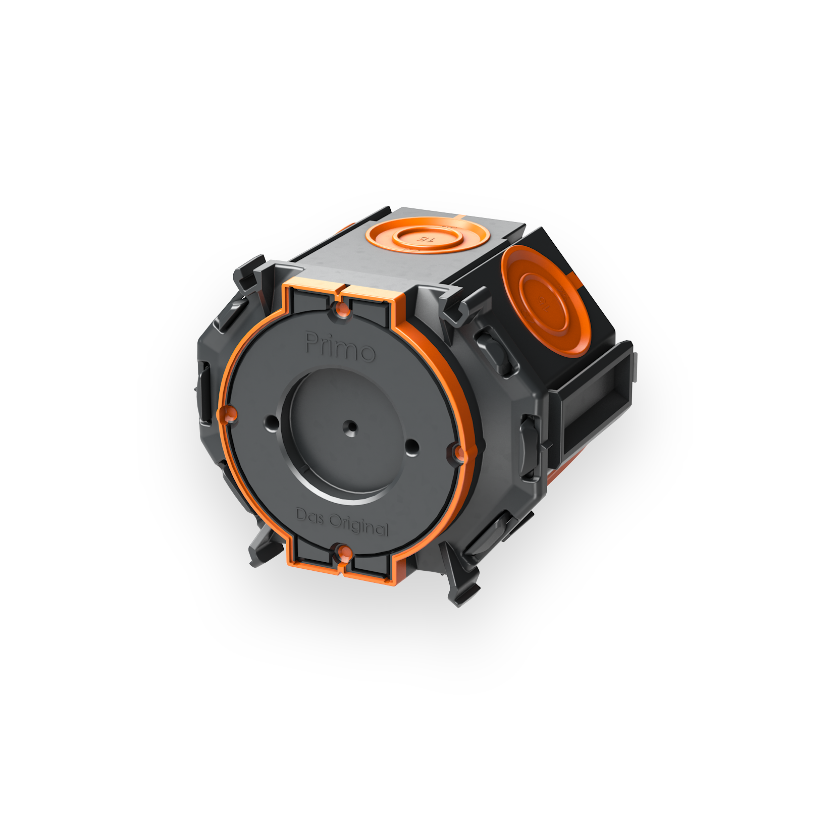

M-Series Concrete Boxes

With the individually usable concrete boxes of the M-Series you not only save a lot of time in the production of your prefabricated slabs and minimize the storage costs in your precast factory, you also deliver your clients the best possible quality of the final product. The innovative membrane technology of the M1, M2 and M3 boxes is absolutely impermeable to concrete and the conduit grip ensures reliable strain relief. See for yourself!

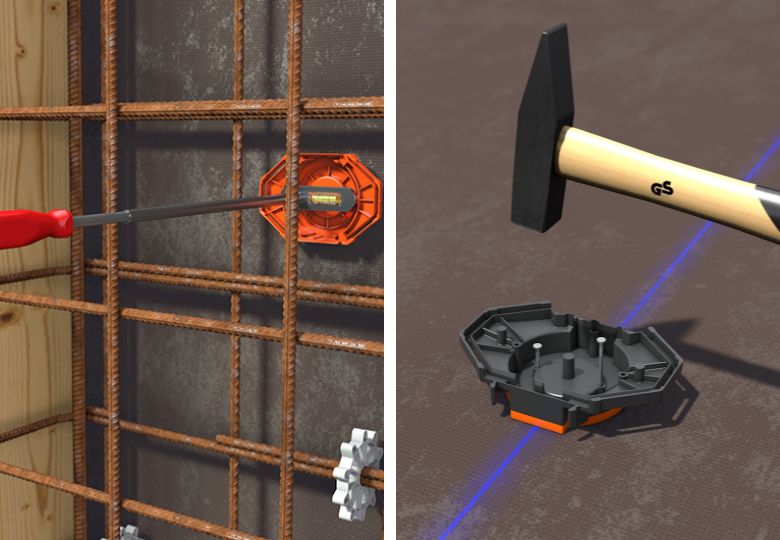

The special highlight: In order to attach the concrete box a magnet can be positioned precisely in just a few seconds either manually or automatically on the formwork. In addition to a higher quality of the final product and a lot of time saving, bothersome removal of glue residue is no longer necessary. On top of that are the magnets recyclable and therefore more environmentally friendly compared to conventional methods. Of course the M-Series products can be glued on the formwork, too.

And Action!

The concrete boxes from the M-Series

The concrete boxes of the M-Series are available in three different sizes:

All variants of the M-Series are available with a 60 mm or a 35 mm installation opening, are 100 percent airtight and can be used for a concrete cover of 20 – 60 mm. The polypropylene membrane boxes are heat-resistant from -5°C to 100°C. Due to the smart design, the following areas of application are possible:

Downloads:

M-SERIES FROM PRIMO

Your advantages in precast factories

Easy assembly

in just a few steps

1

Option 1: Attach the cover of the membrane box to the wall (left) or ceiling (right) at the marked point using nails. If the reinforcement has already been installed, the Primo Nailer helps with simple and injury-free fastening. The wall and ceiling mounting processes are identical.

2

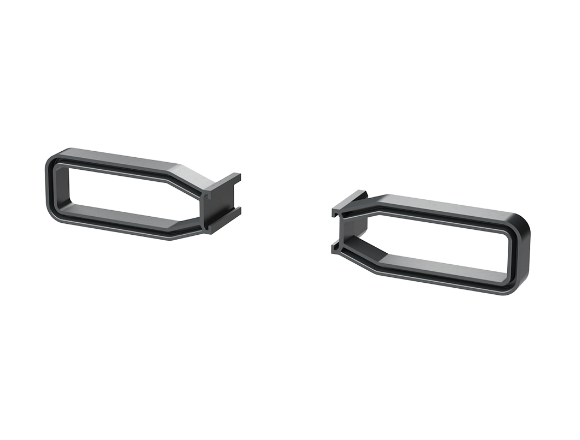

Option 2: Attach membrane boxes directly to the reinforcement using the optional Wings.

3

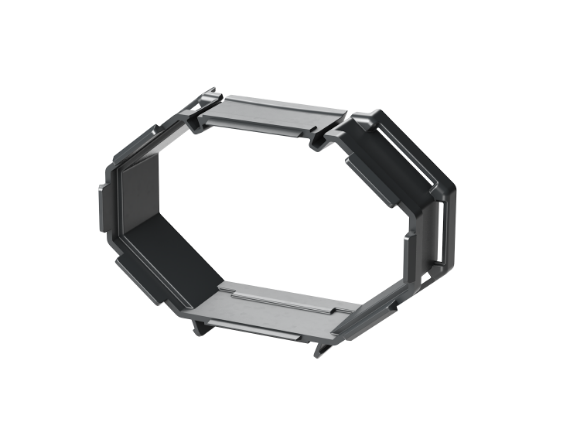

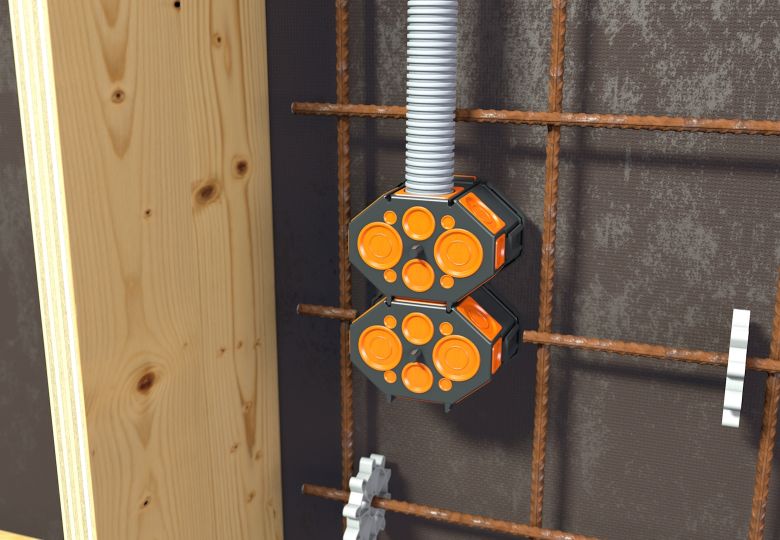

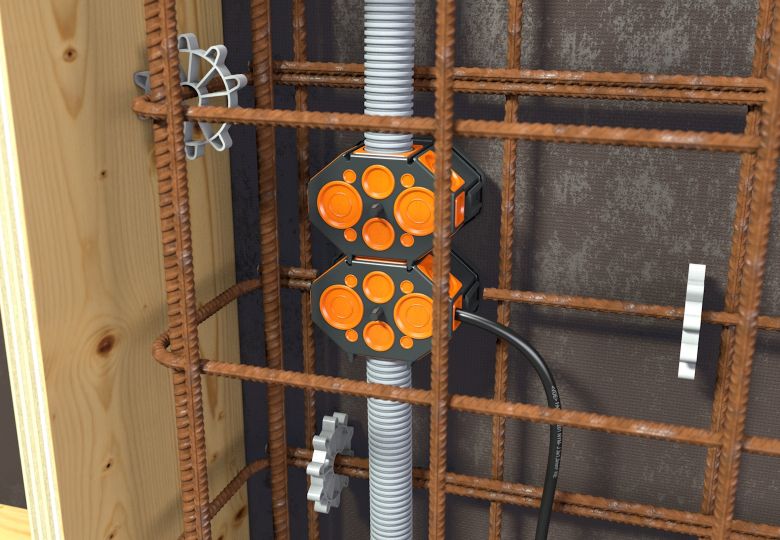

A second concrete box can be easily attached at a standardized distance of 71 mm thanks to SCS connection technology.

4

Thanks to SCS connection technology, two membrane boxes can be easily and stably joined together and placed on the attached covers.

5

Cut the membrane with a cutter knife.

6

Insert conduits as required without additional tools.

7

Attach the second reinforcement and pour the concrete.

8

Knock in the cover after concreting.

9

Remove the SCS connection web effortlessly with the Primo Box Cutter.

10

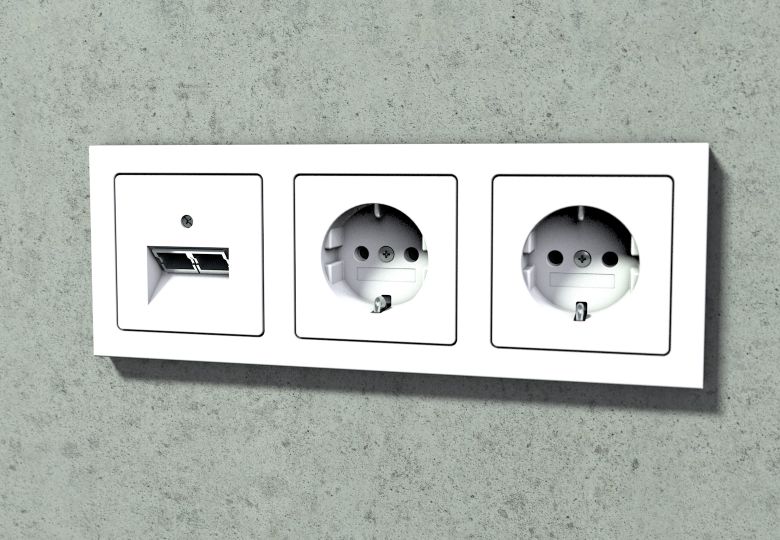

Install prewired devices.

11

Complete installation.

Accessories for the M-Series

YOU MIGHT ALSO BE INTERESTED IN:

Further solutions for precast factories

Is the M1 suitable for all wall thicknesses?

For different wall thicknesses, we have the M1 (installation depth: 85 mm), the M2 (installation depth: 68 mm) and the M3 (installation depth: 48 mm) in our range. A matching Push-on Frame extends the box by 2.5 cm for even more installation space.

For narrow luminaire bases, there is also a cover with a 35 mm luminaire outlet for every box in the M-Series.

Which installations can be made with the M1?

With the M1, you have the huge advantage that you only need one box for the entire concrete installation. The M1 can be used as a junction box, concrete wing box, ceiling junction box, large conduit box or electronics box. Not only does this reduce your storage costs, but there is also no risk of the fitter picking up the wrong product.

Are multiple combinations possible with the M-Series?

Yes, thanks to the SCS connection technology, the M-series boxes can be easily and securely lined up at a standardized distance of 71 mm.

Can the installation space of the M1 be extended unlimited?

For more installation space in the box or for exact positioning of the conduit entry, the Push-on Frame is mounted directly onto the M1. The Frame was also designed with SCS connection technology to ensure a consistently stable connection for multiple boxes.

How is the conduit prevented from slipping out of the box during concreting?

Thanks to the conduit grip of the membrane boxes, they are absolutely concrete-tight and ensure reliable strain relief.

Does the conduit grip also work with coated concrete conduits?

Yes, it works perfectly. We recommend our concrete pipe as the perfect combination for the Primo concrete construction program.

Are component parts such as a conduit coupling required when inserting (several) conduits?

Can the membrane technology withstand the pressure of concrete?

Yes, it’s been tested. We also have many satisfied customers who use our concrete boxes.

How are the M-Series boxes attached to the formwork?

The M-Series boxes can be positioned using magnets (manually or with a robot), glued in the classic way or attached to the reinforcement with the Wings.

How can the M-Series boxes be attached to the formwork-free side during solid wall production?

There are two options: You use the M-Series Wings or the Extension Units.

Does the Wings hold on the M-Series?

Yes, the Wings hold on to all Primo concrete products: Membrane Boxes, Installation Housings, Universal Junction Boxes, Grommets, Sleeves and Wall and Ceiling Transitions.

Do you have any questions about our products? We are there for You