Primo

Company History

This is us

What does Primo do?

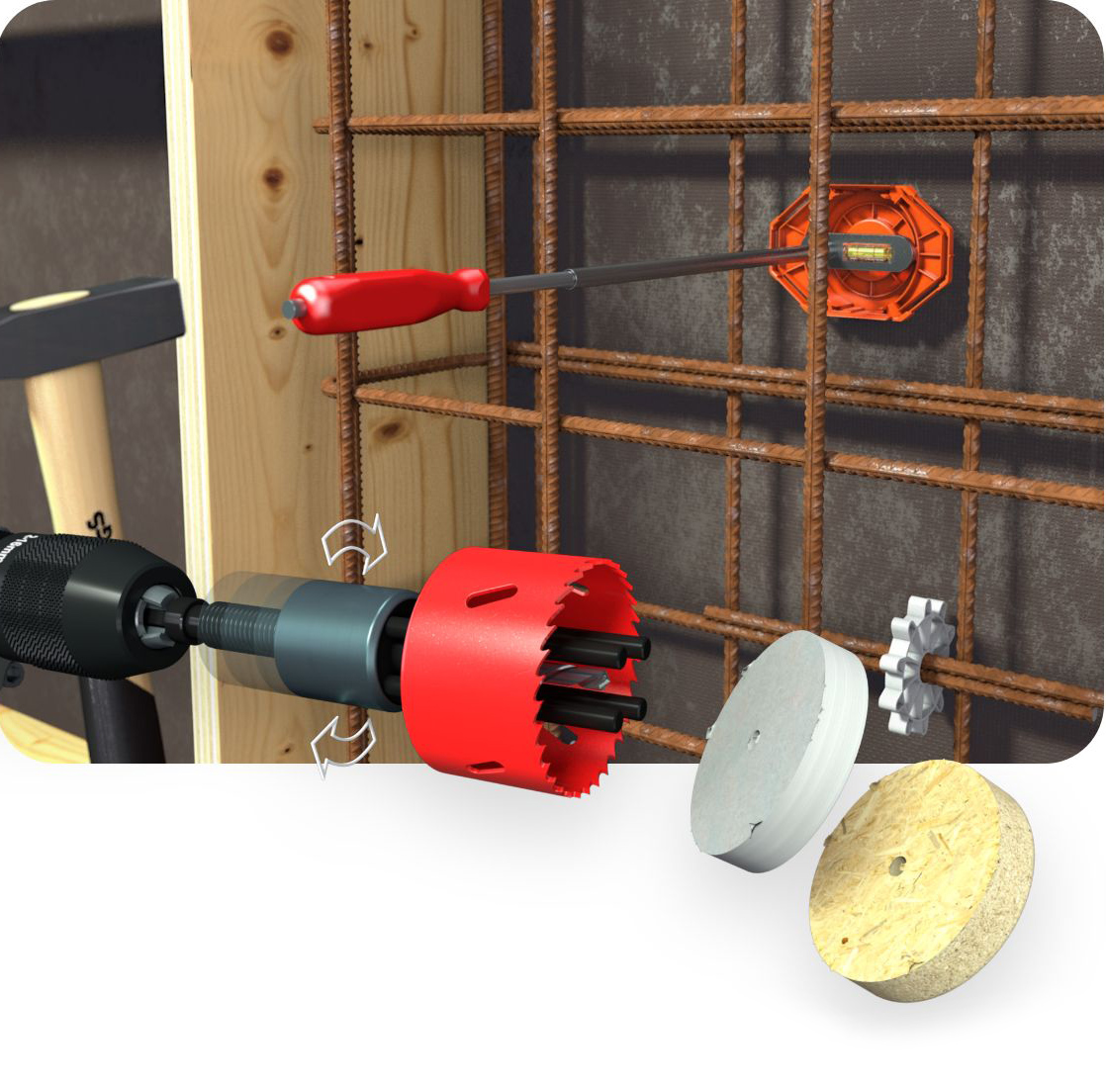

Primo GmbH aims to revolutionize electrical installation with innovative products and tools. Originating from a family-owned electrical installation business, we understand the challenges faced by tradespeople on construction sites. Therefore, we have developed new methods and materials for flush-mounting, concrete, and cavity wall installations.

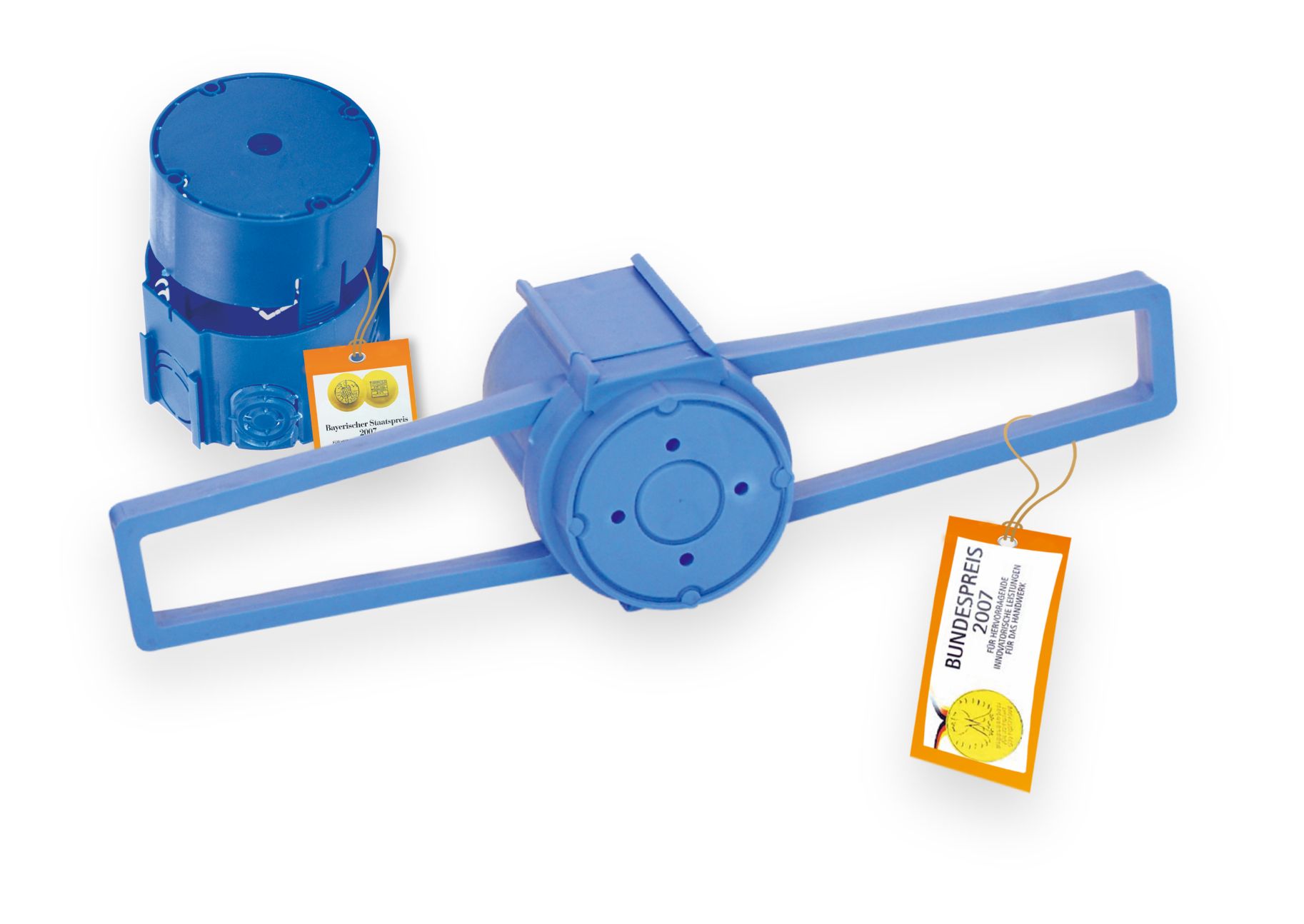

Our innovations make installation easier and faster – you save more than two-thirds of your working time and can even eliminate unnecessary steps entirely. Our sophisticated product range with practical multi-application options helps you counteract the shortage of skilled workers and minimize your storage costs. Our products stand for quality Made in Germany and have already received numerous awards.

Step by step towards the fulfillment of our vision

“Craftsmen are the backbone of society. That is why we must pay particular attention to these industrious and hard-working people. The work involves great effort, but the methods and products are impractical and long outdated. I can still remember my blistered, scuffed hands after drilling exploratory holes in dry walls or the countless 25 kg plaster sacks that I lugged up to the 3rd floor. That must change!

I want to develop sustainable products and processes that facilitate daily work. Value creation must stay in the craft sector to secure their existence. Electricians and electrical engineers should concentrate enthusiastically on their task. I have a vision to revolutionise the trade and I have been working on this with an incredible team for over 15 years.”

Thomas Wintersteiger | Managing Director

Our

Story

oder schäumst Du schon?Von der Branche belächelt, von den Kunden skeptisch beäugt – 2016 sorgte die Primo für Aufsehen in der Elektrobranche! Plötzlich sollen Unterputzdosen nicht eingegipst, sondern eingeschäumt werden. Geht ja gar nicht? Wir sagen: geht jawohl und der Erfolg gibt uns Recht! Anstatt schwere Gipssäcke, Wassereimer und Rührgeräte auf die Baustelle zu schleppen, wird für die Unterputzinstallation eine Schaumdose des Primo Thermoschaums genutzt und das absolut wärmebrückenfrei und luftdicht! Wie sieht’s aus? Gipst Du noch oder schäumst Du schon?