TIME SAVING

With our innovative products, you can save up to 70 percent of your working time compared to conventional electrical installation methods.

Because your time is valuable!

WORK EASIER

Our clever installation materials make your work on the construction site easier and even eliminate unnecessary work steps completely.

This way, each of your jobs becomes your favorite project!

MULTIPLE APPLICATION

Our well-thought-out product range with practical multiple uses helps you counteract the shortage of skilled workers and minimize your storage costs.

One product for the entire construction site!

Cavity Wall Box System from Primo

All advantages at a glance

Installation of the UniQ Cavity Wall Box

UNIQ: FASTER INSTALLED, MORE SPACE

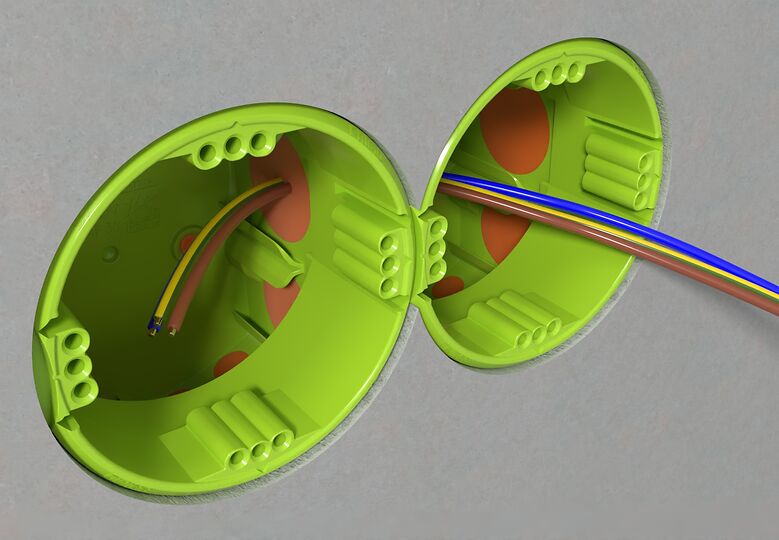

The halogen-free and airtight UniQ Device V-Box for all wall thicknesses from 25 mm offers significantly more installation space than conventional electronical boxes thanks to its 74 mm diameter, hexagonal design, and 73 mm depth. This makes it also suitable for use as an electronics box.

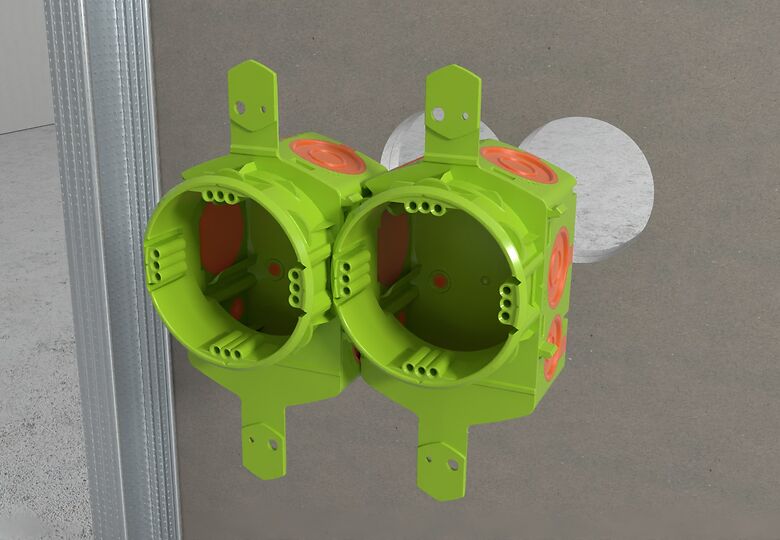

For multiple combinations, the installation boxes can be firmly connected to one another at the standardized combination spacing of 71 mm. The SCS connection technology with a large-area connection membrane including Cable-Plopp technology enables easy through-wiring – without connecting pieces! This further reduces installation time. Three screw bosses on all four sides ensure straight installation by individually aligning the devices.

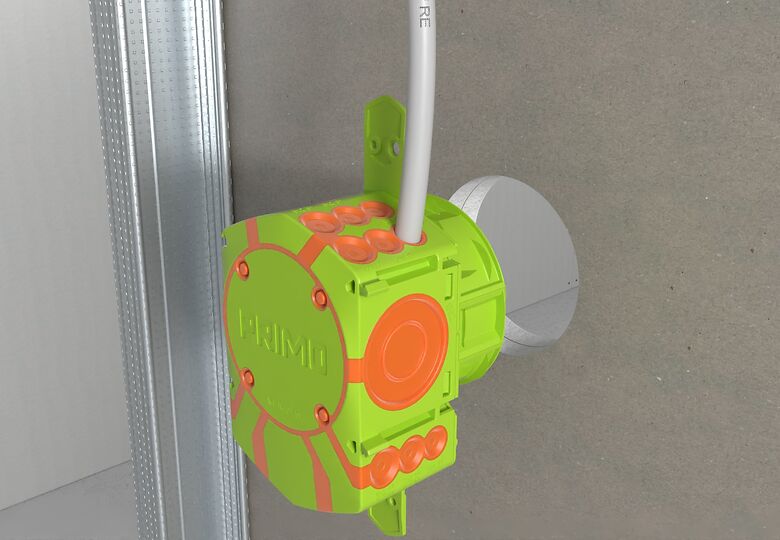

When installed from the rear, fixing slats ensure a firm hold in the building material. Additionally, the junction box can be secured using nails, tackers, or screws.

Downloads:

Easy assembly

in just a few steps

1

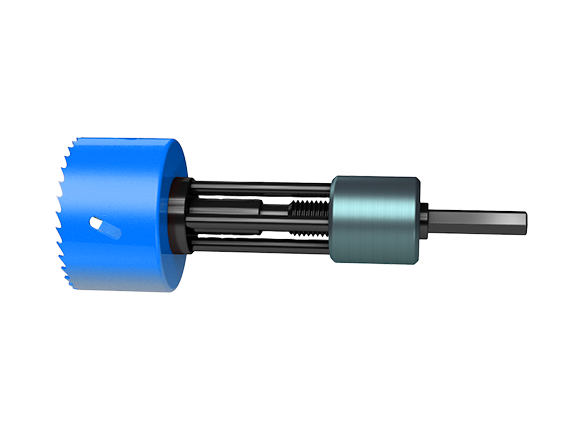

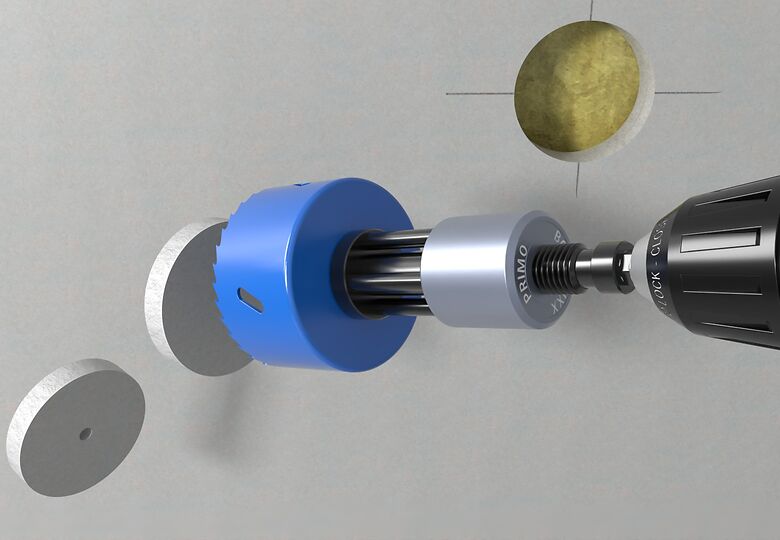

Mark the first box and drill it out from the front using the Primo Bohr-Fixx and a 74 mm hole saw.

2

Easy removal of the drill cores through automatic ejection of the drill core with the Bohr-Fixx.

3

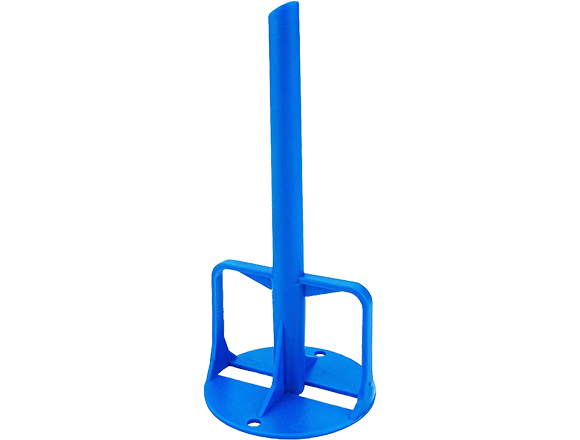

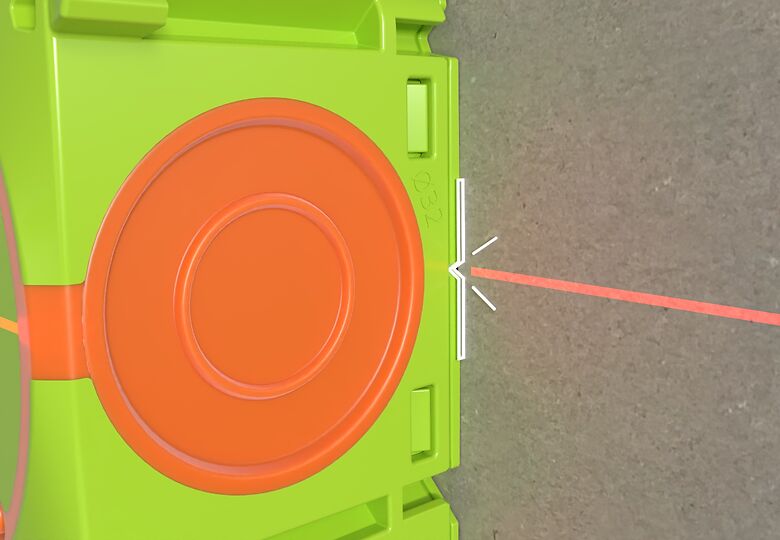

For multiple combinations, insert the Drilling Template into the first hole. Align using the integrated spirit level and tighten the lever. Drill more holes with standardized combination spacing of 71 mm by moving the Drilling Template.

4

Stable connection thanks to SCS connection technology.

5

Insert cables and conduits with the Cable-Plopp completely tool-free. Reliable strain relief for corrugated conduits is provided by the conduit grip.

6

Quick assembly through reverse installation.

7

Precise positioning thanks to integrated marking on the box.

8

Easy and time-saving through-wiring thanks to the large-area connection membrane.

9

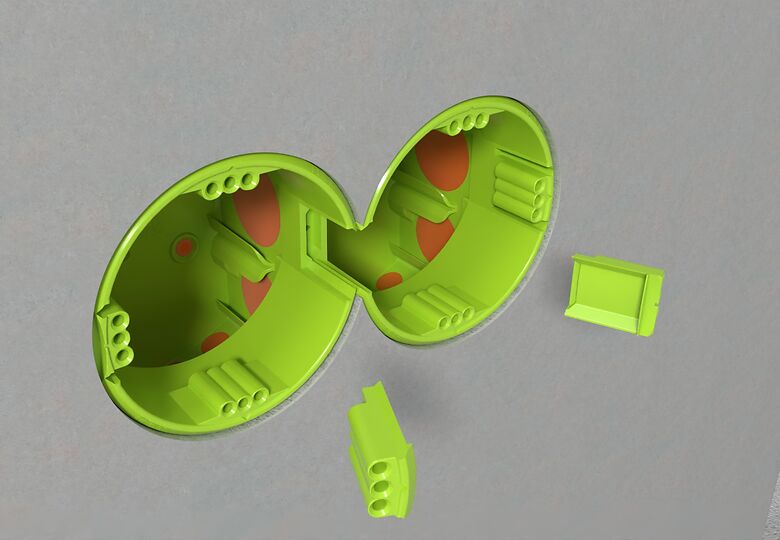

If necessary, the SCS connecting bar can be broken out.

10

Suitable for all drywall materials with a wall thickness of 24 mm or more.

11

Simple installation of pre-wired devices thanks to SCS connection technology.

12

Flexible alignment of the built-in devices thanks to 4×3 screw domes.

13

Completed installation.

Accessories for the fastest Cavity Wall Box System in the world

YOU MIGHT ALSO BE INTERESTED IN:

Further solutions for cavity wall installation

How has to be drilled for the Q-Series? Will a 68 mm drill bit fit?

No, for the Primo Q-Series Cavity Wall Boxes, a hole must be drilled using a 74 mm drill bit.

What is the advantage of the installation diameter of 74 mm?

With a diameter of 74 mm, the installation space is significantly larger than that of conventional electronical boxes. For multiple combinations, the Q-Series boxes can be firmly connected to one another at the standardized combination distance of 71 mm – before installation. The SCS connection technology with its large-area connection membrane including Cable-Plopp technology enables easy through-wiring without connecting pieces. This saves you significant time!

Why does the Qnect/UniQ cost more than a standard cavity wall box?

The Q-Series Cavity Wall Boxes are all halogen-free and airtight, offering numerous advantages and application possibilities in a single box. With a diameter of 74 mm, the installation space is significantly larger than that of conventional electronical boxes. For multiple combinations, the boxes can be firmly connected to one another at the standardized combination distance of 71 mm. The SCS connection technology with its large-area connection membrane including Cable-Plopp technology enables easy through-wiring without connecting pieces. This noticeably saves you working time!

Thanks to its mounting claw, the Qnect can be fixed to panels with a thickness of 0 mm to 37 mm — something that’s not possible with standard cavity wall boxes. In addition, the box features a total of 8 screw domes, allowing flexible alignment. When installing the UniQ from the rear, no screwing is required at all, resulting in significant time savings.

Can the UniQ Reverse Cavity Wall Box be used as an electronics box?

Yes, as the UniQ is larger than a conventional cavity wall box, it offers significantly more installation space. For multiple combinations, the boxes can be firmly connected to one another at the standardized combination distance of 71 mm. The SCS connection bar can then simply be broken out. This allows for time-saving installation of pre-wired devices.

Do the Q-Series Cavity Wall Boxes provide sound insulation?

Not fundamentally, but that’s why we developed the Qnect Sound Insulation Box. It provides a protection level of 60 dB thanks to sound-absorbing material and sound-optimized membranes.

Do the Q-Series Cavity Wall Boxes offer cable retention?

Yes, the Q-Series Cavity Wall Boxes offer secure cable fixation through cable retention up to 2 kg / 20 N.

When installing the UniQ from the rear, is the hole drilled from the front or the back?

With the UniQ, we recommend drilling the hole from the front. This allows you to mark and drill the boxes precisely according to the installation plan. It also creates a cleaner hole, as drilling from the back risks fraying the drywall, for example.

Does working with the Drilling Template take longer?

The big advantage is that you only have to mark the hole once. There’s no need for subsequent alignment of the box. Our Bohr-Fixx is the perfect accessory for this. Turning the screwdriver or drill clockwise cuts an opening in hollow walls, e.g., made of wood, plasterboard, or mineral fiber; turning it counterclockwise ejects the drill core fully automatically and effortlessly.

Do you have any questions about our products? We are there for You

“Thanks to the innovative Primo systems, we’ve achieved significant time savings. In times of skilled labor shortages, this is one of the most important factors. If you don’t have people on site, you should at least save time at work.”